About Us

Welcome!

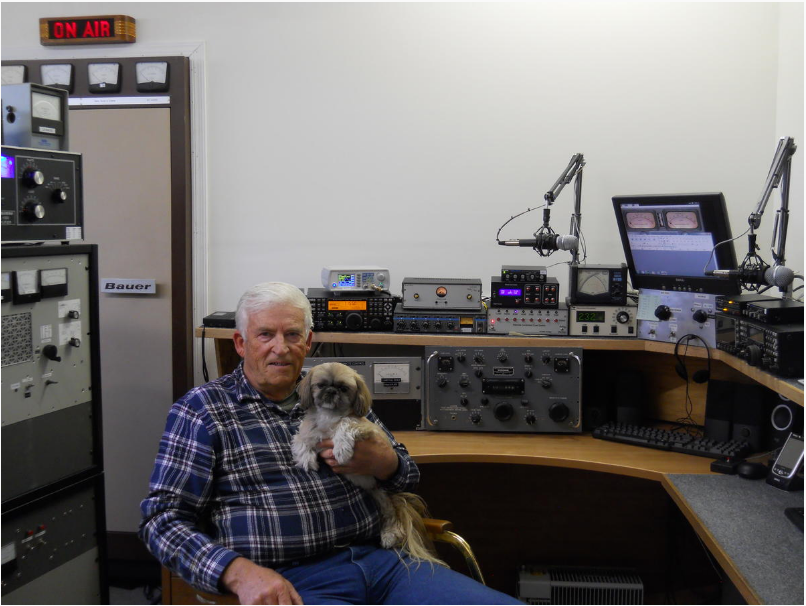

My name is Gary Baker, K7EMF. I took over this business in February 2021, formerly owned by Brian Duerr, WB2JIX.

I am carrying on the tradition of manufacturing, selling and supporting the classic W7FG True Ladder Line and Antenna.

I was sold on the performance from the moment I started using ladder line many years ago. Using a non-resonant, ladder line fed dipole for multiple bands can be one of the most efficient antennas designed! Having a commanding signal on the lower bands with a multi band single radiator is contingent on “system efficiency”. That’s where low loss feedline (Ladder Line) with high SWR comes into play. I'll never go back to coax-fed multi band dipoles. Neither will you when you try one! That's a promise. These antennas have a 30 + year history and I plan to see to it that they have another 30 or more. Thanks so much for taking the time to check out our small business. I hope to make you a convert.

Thank you very much and 73!

Gary, K7EMF

Molly--The one doing all the work and customer interface!

My name is Molly, Gary's daughter and the person fulfilling your TrueLadderLine and Antenna orders. I build all the orders and I attempt to get your order out by the next business day!

The ladder line and antennas are about as simple as you can get, although they require a considerable amount of time & effort to construct. ALL of the spreaders, the center insulator and the end insulators, are custom-built from UV resistant, Polyethylene tubing. We have a proprietary punching and notching system made especially for us, which has been in constant use since the late 1980's. Everything is hand constructed to order. We DO NOT stock antenna inventory.

Each antenna is literally made of pieces of Poly tubing and two pieces of wire. This simplicity, combined with high quality, USA made materials, is the reason why these antennas perform so well for many, many years. They are lightweight with a very low wind load.

The wire is 16GA, 26 strand, 100% copper, PVC coated and UV resistant as well. We measure each length of wire to the correct dimensions, stretch them out through a custom jig to be able to snap on all of the spacers. Then we thread both ends of the antenna through the support holes in the center piece and run them out to the final length to the end insulators. You can imagine the time involved to construct a 160-10M dipole with 200' of feedline. It's very time-consuming. That's the reason why customers always state that it really is easier and less expensive than attempting to build your own.

Our customers have been very kind and gracious to me which motivates me to supply the best product possible.

Sincerely,

Molly

Manager, Manufacturing

TrueLadderLine is now open and taking/shipping orders! Thank you for your support!

Best 73's, Gary Baker K7EMF